- Home

- News

- Why Choose Solar DC Cables for Solar Power Stations? What is the difference between Normal DC cables and Solar DC cables?

Why Choose Solar DC Cables for Solar Power Stations? What is the difference between Normal DC cables and Solar DC cables?

Solar DC Cable

A large number of DC cables in solar power stations need to be laid outdoors, and the environmental conditions are harsh. The cable materials should be based on the resistance to ultraviolet rays, ozone, severe temperature changes and chemical erosion. Long-term use of ordinary materials in this environment will cause the cable sheath to be fragile and even decompose the cable insulation. These situations will directly damage the cable system, and at the same time will increase the risk of cable short circuit. In the medium and long term, the possibility of fire or personal injury is also higher, which greatly affects the service life of the system.

Therefore, it is very necessary to use solar dc cables and components in solar power stations. Special photovoltaic cables and components not only have the best resistance to wind and rain, UV and ozone erosion, but also can withstand a wider range of temperature changes (for example: from -40 to 125°C). In Europe, technicians have passed tests and the measured temperature on the roof is as high as 100-110°C.

How to choose Solar DC Cables for Solar Power Plants?

From the cable conductor material:

In most cases, the DC cables used in solar power stations are used for outdoor long-term work. Due to the limitation of construction conditions, connectors are mostly used for cable connection. Cable conductor materials can be divided into copper core and aluminum core. Copper core cable has better oxidation resistance than aluminum, long life, good stability, low voltage drop and low power loss; in construction, because the copper core is flexible and the allowable bend radius is small, it is convenient to turn and pass through the pipe; and the copper core is resistant to fatigue and repeated bending is not easy to break, so the wiring is convenient; at the same time, the copper core has high mechanical strength and can withstand greater mechanical tension, which brings great convenience to construction and laying, and creates conditions for mechanized construction. On the contrary, aluminum core cables are prone to oxidation (electrochemical reaction) in the installation joints due to the chemical properties of aluminum materials, especially creep phenomena, which can easily lead to failures.

Therefore, copper cables have outstanding advantages in the use of solar power stations, especially in the field of directly buried cable power supply. It can reduce the accident rate, improve the reliability of power supply, and is convenient for construction, operation and maintenance.This is the reason why copper cables are mainly used in underground power supply in China.

Advantages of solar power cables:

High temperature resistance, cold resistance, oil resistance, acid and alkali salt resistance, UV resistance, flame retardant, environmental protection, solar power cables are mainly used in harsh environments with a service life of more than 25 years.

Solar cables are often exposed to the sun, and solar systems are often used in harsh environments, such as low temperature and ultraviolet radiation. At home or abroad, when the weather is good, the highest temperature of the solar system will be as high as 100℃. The various materials that can be used for ordinary cables are high-quality interwoven link materials such as polyvinyl chloride (PVC), rubber, TPE and XLPE, but it is a pity that the highest rated temperature for ordinary cables In addition, even PVC insulated cables with a rated temperature of 70°C are often used outdoors, but they cannot meet the requirements of high temperature, UV protection, and cold resistance. It can be seen that solar power stations should choose reliable solar dc cables.

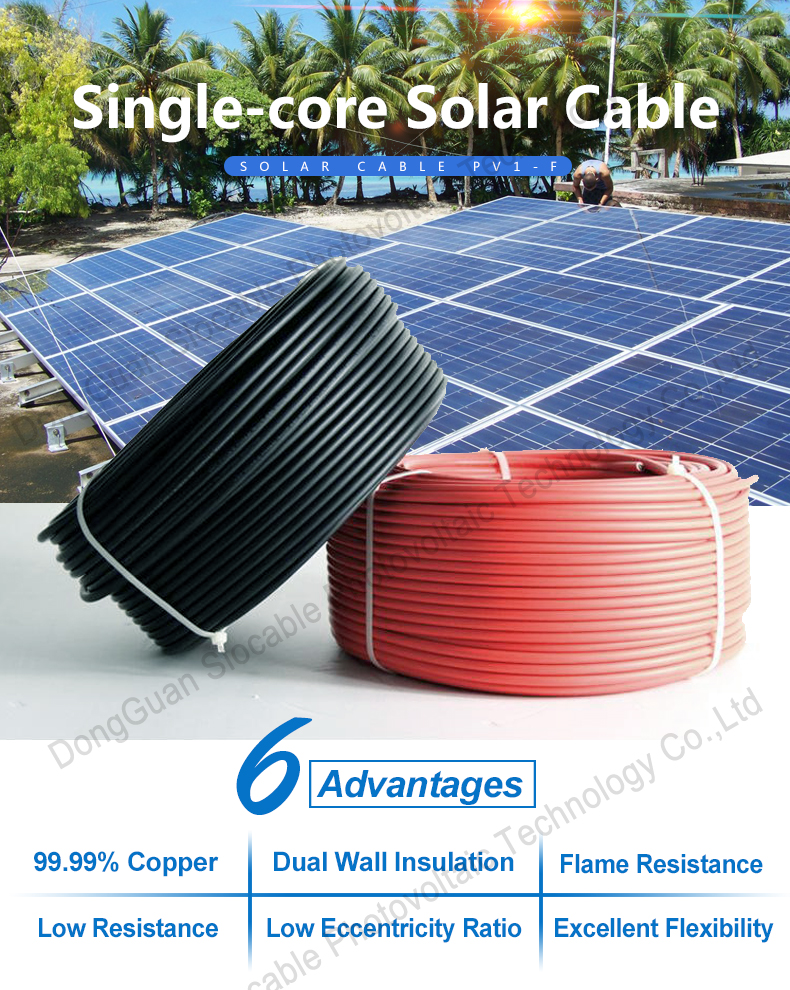

Advantages of slocable solar dc cables

What is the difference between Normal DC cables and Solar DC cables?

From the point of view of cable insulation sheath material:

| Normal DC cables | Solar DC cables | |

| insulation | Irradiation cross-linked polyolefin insulation | PVC or XLPE insulation |

| jacket | Irradiation cross-linked polyolefin insulation | PVC sheath |

During the installation and operation and maintenance of solar power stations, cables may be routed in the soil below the ground, overgrown with weeds and rocks, on sharp edges of the roof structure, and exposed to the air. The cables may bear various external forces. If the cable sheath is not strong enough, the cable insulation layer will be damaged, which will affect the service life of the entire cable, or cause short-circuit, fire, and personal injury hazards. Cable scientific research and technical personnel found that the material cross-linked by radiation has higher mechanical strength than before radiation treatment. The cross-linking process changes the chemical structure of the polymer of the cable insulation sheath material, the fusible thermoplastic material is converted to non-fusible elastomeric material, and the cross-linking radiation significantly improves the thermal, mechanical and electrical properties of the cable insulation material. Chemical properties.

The DC loop is often affected by a variety of unfavorable factors during operation, resulting in grounding, making the system unable to operate normally. Such as extrusion, poor cable manufacturing, unqualified insulation materials, low insulation performance, aging of the DC system insulation, or certain damage defects that can cause grounding or become a grounding hazard.

From the perspective of machine load resistance:

For solar dc cables, during installation and application, the cables can be routed on the sharp edges of the roof layout. At the same time, the cables must withstand pressure, bending, tension, interlaced tensile loads and strong impact resistance, which is superior to normal dc cables. If you use normal dc cables, the sheath has poor UV protection performance, which will cause the outer sheath of the cable to age, which will affect the service life of the cable, which can lead to the appearance of short-circuits, fire alarms, and dangerous injuries to employees.

After being irradiated, the solar dc cable insulation sheath has the properties of high temperature resistance, ultraviolet radiation resistance, oil resistance, and cold resistance. The service life is more than 25 years, which is incomparable with normal dc cables.

Recommended products

OEM Factory for House Solar Single Core Copper Wire

Slocable TUV Solar Panel Cable 4mm 1500V

Slocable Double-Core Solar Cables used in Solar Power Plant

Slocable 6mm Twin Core Solar Cable