Intelligent PV Panel Junction Box Solves Three Major Problems that Plague the PV Industry

In the past 10 years, photovoltaic power generation products have become more and more popular around the world, and innovations around the photovoltaic industry emerge in endlessly. These innovative measures have promoted the continuous improvement of the efficiency of photovoltaic power generation systems, lower costs, and make the photovoltaic system more grounded and closer to residents’ lives.

Among these innovative measures, the intelligent R&D of photovoltaic power generation systems has become one of the core concerns of global technological innovation. Some pioneering photovoltaic companies and research institutions use Internet technology, sensor technology, big data analysis, etc. to interconnect the isolated photovoltaic power station systems to help investors make more convenient daily safety maintenance and investment income analysis decisions.

Forming the core of the solar power system – solar panels, it bears the basic role of receiving light and converting light energy into electrical energy. However, over the years, most of the so-called intelligent photovoltaic power plants that have claimed to have installed an intelligent management platform have still not seen any traces of “intelligence” on the basic level of power generation core modules (panels). The solar panels are simply connected in series by the installer to form a string, and several strings are connected to form a photovoltaic array, which finally forms a power station system.

So, is there any problem with this arrangement?

First, the voltage of each photovoltaic panel is not high, only a few tens of volts, but the voltage in series is as high as about 1000V. When the power generation system encounters a fire, even if the firefighters can disconnect the return circuit switch of the main circuit, the whole system is still very dangerous, because it is only the current in the return circuit that is turned off. Because the solar panels are connected with each other by connectors, the voltage of the system to the ground is still 1000V. When inexperienced firefighters end up high-pressure water guns to spray water on these 1000V power generation boards, because the water is conductive, the huge voltage difference is directly loaded on the firefighters through the water column, and a disaster will occur.

Second, the output characteristics of each photovoltaic panel are inconsistent, such as current, voltage and optimal operating point. With the long-term use and natural aging of photovoltaic systems outdoors, this inconsistency will become more and more obvious. The characteristics of tandem power generation conform to the “barrel effect”. In other words, the total power generation of a string of solar panels depends more on the output characteristics of the weakest panel in the string.

Third, solar panels are most afraid of shadow occlusion (the occlusion factors are often tree shade, bird droppings, dust, chimneys, foreign objects, etc.), so they are generally installed in sunny places, but in distributed rooftop power generation systems In order to consider the beauty and coordination of the overall house and courtyard building structure, the owners often spread the battery panels evenly on the entire roof. Although some parts of these roofs may cause shadow occlusion, sometimes, the owners do not fully understand the serious impact and harm of shadow occlusion on electric panels. Since the battery panel is shaded by shadows, the bypass protection element (usually a diode) in the PV panel junction box behind the panel will be induced, and the DC current up to about 9A in the battery string will be instantaneously loaded on the bypass device, making the PV junction box There will be a high temperature of more than 100 degrees in the interior. This high temperature will have little effect on the battery board and the junction box in the short term, but if the shadow effect is not eliminated and exists for a long time, it will seriously affect the service life of the junction box and the battery board.

Moreover, some shadows belong to high-frequency repeated shielding (for example, the branches in front of the home photovoltaic roof will repeatedly block the battery panel with the wind. This high-frequency alternating shielding makes the bypass device in a cycle: disconnection – conduction – disconnection). The diode is turned on and heated by the high-power current, and then the bias is reversed instantaneously to cancel the current and increase the reverse voltage. In this repeated cycle, the service life of the diode is greatly reduced. Once the diode in the PV panel junction box burns out, the system output of the whole solar panel will fail.

So, is there a solution that can solve the above three problems at the same time? Engineers invented the intelligent PV junction box after years of hard work and practice.

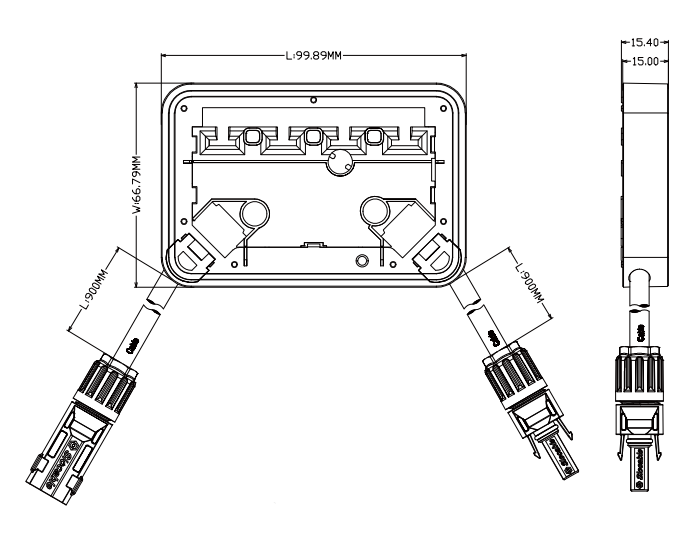

This Slocable PV junction box uses a dedicated DC photovoltaic power management chip to design and build a control circuit board, which can be directly installed in the photovoltaic junction box. In order to facilitate the installation of solar panel manufacturers, the design has reserved four bus-band wiring outlets, so that the junction box can be easily connected to the solar panel, and the output cables and connectors are pre-installed before leaving the factory. This junction box is currently the most convenient PV intelligent junction box in the photovoltaic industry to install and maintain. It mainly provides solutions to the above three three major problems that plague the photovoltaic industry. It has the following functions:

1) MPPT function: Through the cooperation of software and hardware, each panel is equipped with maximum power tracking technology and control devices. This technology can maximize the reduction of power generation efficiency caused by different panel characteristics in the panel array and reduce the ” The impact of the “barrel effect” on the efficiency of the power station can greatly improve the power generation efficiency of the power station. From the test results, the power generation efficiency of the system can even be increased by 47.5%, which increases the investment income and greatly shortens the investment payback period.

2) Intelligent shutdown function for abnormal conditions such as fire: In the event of a fire, the built-in software algorithm of the PV panel junction box and the hardware circuit can determine whether an abnormality has occurred within 10 milliseconds, and actively cut off the connection between each battery panel. The voltage of 1000V is reduced to a voltage acceptable to the human body around 40V to ensure the safety of firefighters.

3) MOSFET thyristor integrated control technology is used instead of the traditional Schottky diode. When the shadow is blocked, the MOSFET bypass current can be started instantly to protect the safety of the battery panel. At the same time, because of the unique low VF characteristics of the MOSFET, the heat generated in the overall junction box is only one-tenth of that of the ordinary junction box. This technology greatly The service life of the photovoltaic junction box is prolonged, and the service life of the solar panel is better guaranteed.

At present, technical solutions for intelligent PV junction boxes are emerging one after another, mostly around optimizing and improving photovoltaic string power generation efficiency, and improving photovoltaic system fire response mechanisms such as shutdown functions.

Developing and designing a “intelligent PV junction box” is not necessarily a complex and profound work. However, how can the intelligent junction box really meet the pain points and difficulties of the photovoltaic market? It is necessary to find the best balance in terms of the electrical function of the junction box, the service life of electronic devices, the cost and investment income of the intelligent junction box. It is believed that in the next few years, the intelligent PV junction box will have more applications in the photovoltaic system and create more value for investors.